Contact Us

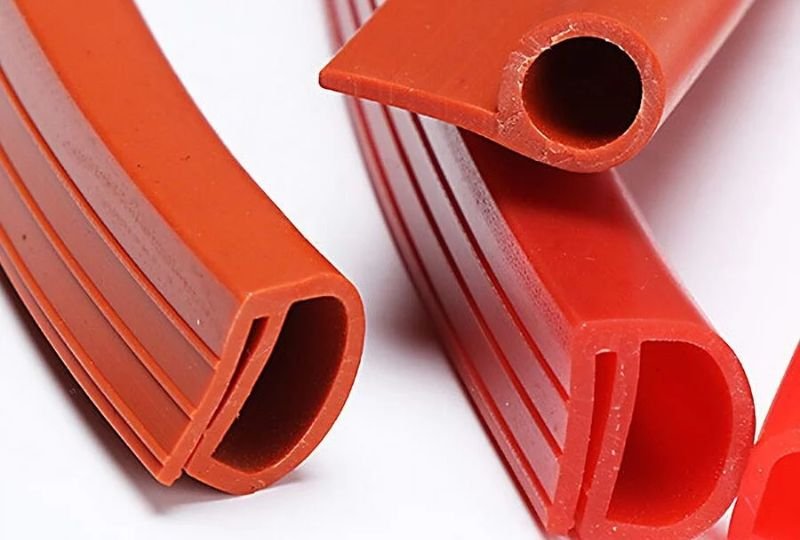

Extrudable Silicone Rubber

General Purpose Extrudable Silicone Rubber is a versatile material with various applications. It is commonly used in gasket and sealing applications due to its excellent resistance to high temperatures and environmental conditions. Its extrudability allows for easy molding and shaping into desired forms. Furthermore, it offers good electrical insulation properties, making it suitable for electrical enclosure seals and wire insulation.

Applications

Tubing, Electric wire

Description

General purpose type heat cured compounds for extrusion.

FEATURES

APPLICATIONS

FEATURES

- Extruded molding Type

- Excellent extrusion properties

- Excellent mechanical properties

- Conform to the FDA 21 CFR 177.2600 certification

- Conform to the RoHS certification

APPLICATIONS

- Tubing

- Electric wire

- General purpose type heat cured compounds for extrusion.

FEATURES- Extruded molding Type

- Excellent extrusion properties

- Excellent mechanical properties

- Conform to the FDA 21 CFR 177.2600 certification

- Conform to the RoHS certification

APPLICATIONS- Tubing

- Electric wire

General purpose type heat cured compounds for extrusion.

FEATURES

APPLICATIONS

FEATURES

- Extruded molding Type

- Excellent extrusion properties

- Excellent mechanical properties

- Conform to the FDA 21 CFR 177.2600 certification

- Conform to the RoHS certification

APPLICATIONS

- Tubing

- Electric wire

General purpose type heat cured compounds for extrusion.

FEATURES

- Extruded molding Type

- Excellent extrusion properties

- Excellent mechanical properties

- Conform to the FDA 21 CFR 177.2600 certification

- Conform to the RoHS certification

APPLICATIONS

- Tubing

- Electric wire

General purpose type heat cured compounds for extrusion.

FEATURES

- Excellent process ability

- Excellent mechanical properties

- Pass RoHS

- Pass LFGB

- Pass FDA 21 CFR 177.2600

APPLICATIONS

- Casing

- Extrusion tube, extrusion casing

- Rubber parts in contact with the food

General purpose type heat cured compounds for extrusion.

FEATURES

- Extruded molding Type

- Excellent extrusion properties

- Excellent mechanical properties

- Conform to the FDA 21 CFR 177.2600 certification

- Conform to the RoHS certification

- Conform to the LFGB certification

APPLICATIONS

- Tubing

- Electric wire

- TDS OF XHG-361

- TDS OF XHG-3051

- TDS OF XHG-TY4366-60

- TDS OF XHG-WRB2800-51

- TDS OF XHG-WRB2800-62

| Type | Grade Name | Density g/cm3 | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Tear strength (KN/m) | Curing Condition |

| extrudable (precipitated filler) |

XHG-351* | 1.16 | 50/52* | 9.9/7.8* | 500/380* | 22/18* | 50% active DBPH, 1.3%; press cure: 10min/115℃ post cure: 2 h/200℃ |

| XHG-361* | 1.20 | 61/64* | 8.9/7.3* | 400/300* | 24/18* | ||

| XHG-371* | 1.20 | 72/74* | 8.7/7.5* | 300/220* | 24/16* | ||

| XHG-381* | 1.23 | 82/84* | 7.0/6.7* | 200/200* | 24/19* | ||

| extrudable (precipitated filler) |

XHG-3031* | 1.110 | 29 | 6.5 | 750 | 16 | 50% active DBPH, 1.3%; press cure: 10min/115℃ post cure: 2 h/200℃ |

| XHG-3041* | 1.113 | 39 | 8.0 | 600 | 17 | ||

| XHG-3051* | 1.16 | 52/55* | 8.9/7.7* | 450/340* | 23/20* | ||

| XHG-3061* | 1.18 | 61/63* | 8.2/7.2* | 350/220* | 22/19* | ||

| XHG-3071* | 1.21 | 70/73* | 8.9/7.9* | 300/240* | 23/18* | ||

| XHG-3081* | 1.24 | 75/78* | 6.5/6.0* | 250/200* | 22/17* | ||

| extrudable (precipitated filler) |

XHG-TY4366-30 | 1.112 | 30 | 6.0 | 700 | 22 | 50% active DCBP, 1.3%; press cure: 10min/115℃ post cure: 2 h/200℃ |

| XHG-TY4366-40 | 1.142 | 40 | 8.0 | 550 | 25 | ||

| XHG-TY4366-50 | 1.188 | 50 | 8.0 | 550 | 30 | ||

| XHG-TY4366-60 | 1.195 | 60 | 8.0 | 450 | 28 | ||

| XHG-TY4366-70 | 1.215 | 68 | 7.0 | 300 | 28 | ||

| XHG-TY4366-80 | 1.245 | 79 | 7.0 | 200 | 22 | ||

| extrudable (fumed filler) |

XHG-WRB2800-41 | 1.11 | 39/39* | 10.3/9.7* | 615/565* | 28/29* | 50% active DCBP, 1.3%; press cure: 10min/115℃ post cure: 2 h/200℃ |

| XHG-WRB2800-51 | 1.15 | 50/52* | 10.0/9.4* | 600/535* | 28/30* | ||

| XHG-WRB2800-61 | 1.17 | 58/62* | 10.5/9.5* | 500/420* | 32/37* | ||

| XHG-WRB2800-71 | 1.19 | 67/68* | 11.0/10.6* | 500/435* | 38/32* | ||

| XHG-WRB2800-81 | 1.22 | 72/76* | 9.1/10.0* | 430/400* | 36/36* | ||

| extrudable (fumed filler) |

XHG-WRB2800-22 | 1.07 | 22/21* | 8.4/7.5* | 1140/800* | 16/17* | platinum catalyst, part A 0.5%;part B 1.1%, press cure: 10min/120℃ post cure: 2 h/200℃ |

| XHG-WRB2800-42 | 1.09 | 40/42* | 9.5/9.8* | 900/865* | 30/29* | ||

| XHG-WRB2800-52 | 1.14 | 47/51* | 9.1/9.4* | 800/770* | 29/31* | ||

| XHG-WRB2800-62 | 1.16 | 59/62* | 9.0/9.5* | 580/600* | 40/42* | ||

| XHG-WRB2800-72 | 1.20 | 75/82* | 9.8/9.0* | 500/330* | 43/25* | ||

| XHG-WRB2800-82 | 1.20 | 79/84* | 10.1/7.9* | 400/220* | 40/35* | ||

| general purpose (fumed filler for extrusion with peroxide) |

XHG-TY4171-30 | 1.12 | 30* | 8.5* | 700* | 25* | DCBP,1.3%; press cure: 10min/120℃ post cure: 2 h/200℃ |

| XHG-TY4171-40 | 1.12 | 39* | 9.0* | 510* | 30* | ||

| XHG-TY4171-50 | 1.15 | 53* | 10* | 380* | 35* | ||

| XHG-TY4171-60 | 1.18 | 62* | 10* | 350* | 30* | ||

| XHG-TY4171-70 | 1.21 | 72* | 10* | 400* | 35* | ||

| XHG-TY4171-80 | 1.23 | 79* | 9.5* | 300* | 35* | ||

| general purpose (fumed filler for extrusion with platinum catalyst) |

XHG-TY5171-40 | 1.13 | 42* | 10* | 620* | 30* | platinum catalyst, part A 0.5%;part B 1.6%, press cure: 10min/120-160℃ post cure: 2 h/200℃ |

| XHG-TY5171-50 | 1.14 | 53* | 10* | 590* | 35* | ||

| XHG-TY5171-60 | 1.17 | 65* | 10* | 400* | 35* | ||

| XHG-TY5171-70 | 1.21 | 79* | 9.0* | 400* | 35* | ||

| XHG-TY5171-80 | 1.23 | 84* | 7.0* | 400* | 30* |